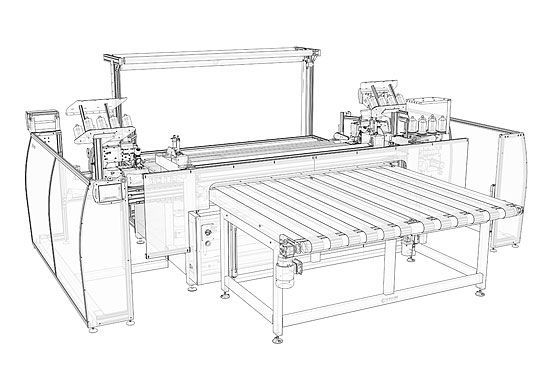

Unique quilting machine in an upright position with 4 sewing heads that move independently, and qualified to work with centred designs, continuous and framed.

Get a high level of flexibility in your production and in the designs of the quilts, guarantying a perfectly quilted closed frame over the panel's perimeter.

These features make the ClevOne a key tool in achieving a strong competitive advantage allowing to adapt to fast-changing trends in the mattress industry.

QUILTING MOTION SYSTEM

A continous flow and control of the input material permits to achieve a high pattern accuracy, independently of materials and thicknesses.

SINGLE-NEEDLE PATTERNS

Doubles productivity in framed patterns with 4 and more motifs.

MATERIAL THICKNESS

Accepts a wide range of materials and thicknesses, between 1 - 8cm, thanks to the exclusive and adapted development of the sewing-heads.

FLEXIBLE PRODUCTION

Enlarges and eases production possibilities, in relation to materials, thicknesses and patterns.

LOCKSTITCH

Enables quilting at high RPM, delivering a strong and reliable seam.

INDUSTRY 4.0. READY

The integration of an advanced electronic architecture enables us to comply with the Industry 4.0 requirements: connectivity, modularity and energy efficiency.

Its four sewing heads with independent movement, moving along the transversal carriage, increase the production of multi-needle drawings up to 2.5 times

Set up your ClevOne.

Optionals

01.

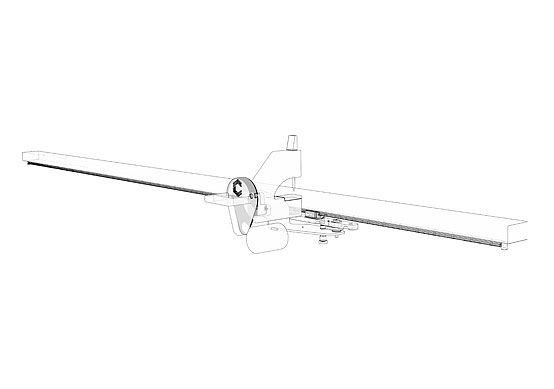

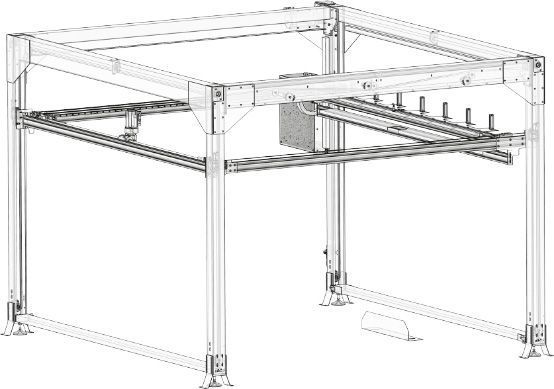

SEWING RAIL SYSTEM

Eases fabric changeovers by allowing the operator to complete this task ergonomically. The rail system is complemented with an auxiliar handy sewing machine that provides a fast and solid seam, reducing interruptions in the manufacturing process.

02.

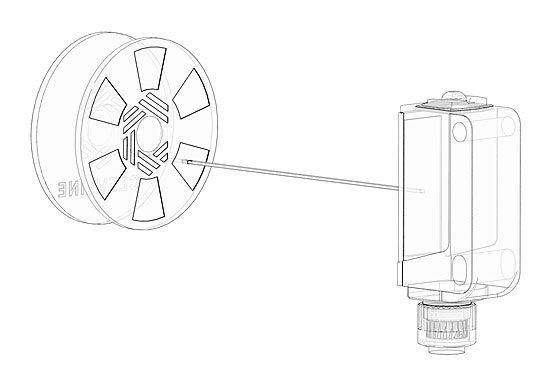

SMART SEAM MONITORING SYSTEM (BOBBIN CASE)

Assures the seam quality by monitoring the thread consumption, and detecting thread breaks; which avoids quality issues in the finished mattress.

03.

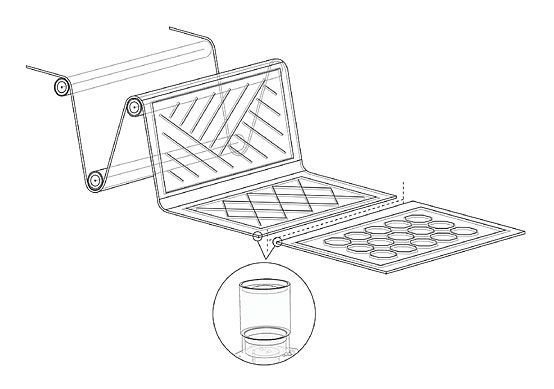

CLEVLINK

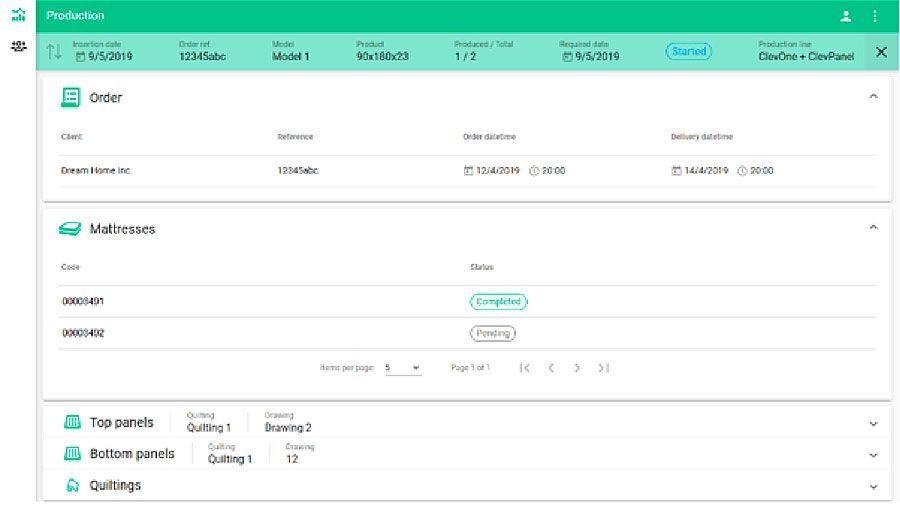

Communicates and synchronises the work-flow between ClevPanel and ClevOne (multi-head quilting machine), by processing a single production list introduced into the ClevOne´s HMI dashboard, including lateral and cross-cutting ClevPanel´s sewing-heads, guarantying a panel with a centred pattern.

04.

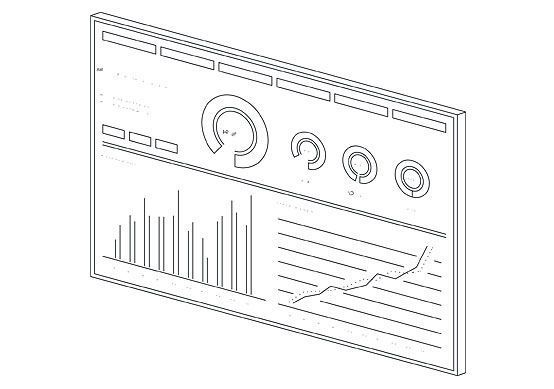

CONNECT

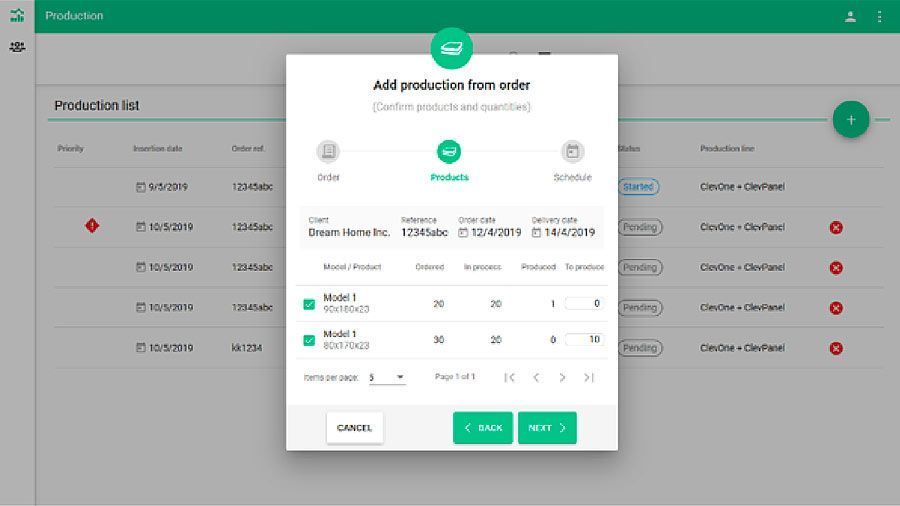

Enables the interaction with your quilting department through production management and visibility over the quilting production in the LIne ClevLine.

In three simple steps allows for the creation of a dynamic and smart production list, that is automatically organised according to your criteria and priorities: material change reduction, delivery dates, and others.

05.

CLEVPANEL

Completes two processes into one cutting and sewing of a quilted panelare completed simultaneously over the panel perimeter, delivering an important reduction in the manufacturing times and input costs, since it eliminates transitional processes and the exceeding edge between panels, needed otherwise for the manual overlock.

ClevPanel´s sewing-heads,exclusively developed, adapt automatically and accuretely to the requested panel measures (between 60-220cm and 140-240cm), working with thicknesses accepted by ClevOne (between 1-8cm), that delivers a perfect finish panel and eases the closing of the mattress.

The high level of integration between ClevOne and ClevPanel allows to manage a production list from a single dashboard.

06.

CLEVSTACKER

Automatic stacking machine for panels that contribute to greater automation of the manufacturing line, fully integrated and synchronized with our Control Panel, controlling both machines from the same control screen.

Automatic stacking machine that contributes to a higher level of automation,with an integration and synchronisation with the ClevOne and ClevPanel, which enables the operator to manage both machines from a single HMI dashboard.

The ClevStacker piles panels up in different working modes, and up to 2 metres high without operator´s interaction for roughly 30 minutes, thus reducing product manipulation and eliminating repetitive tasks.

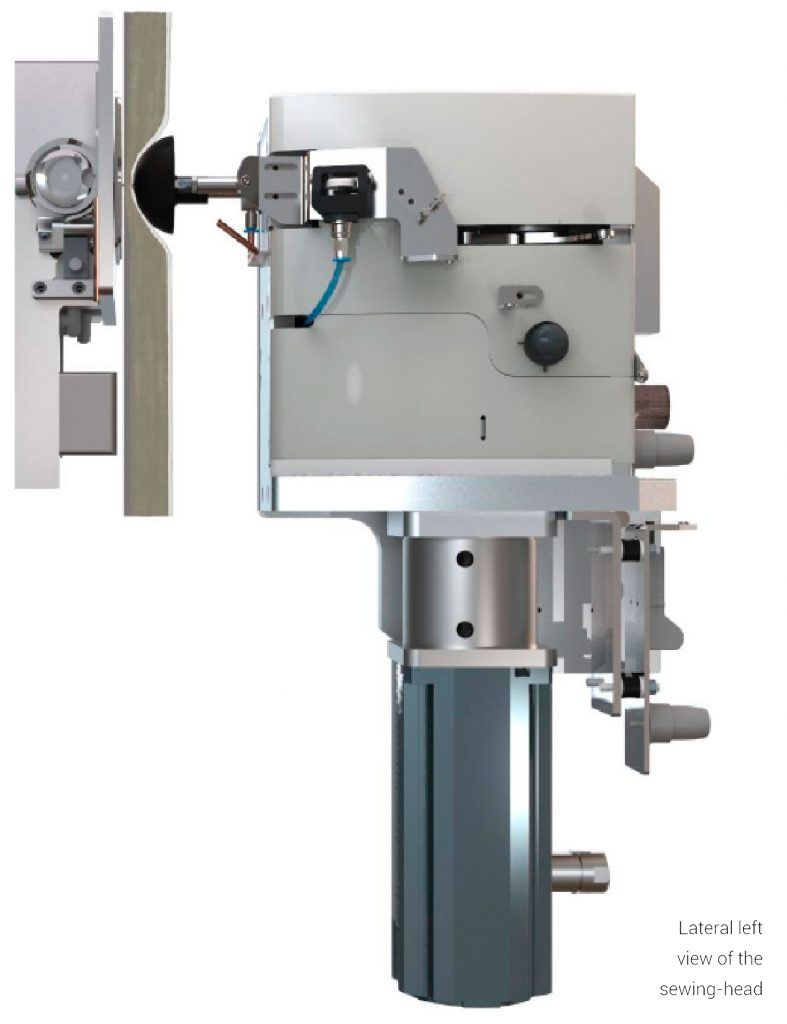

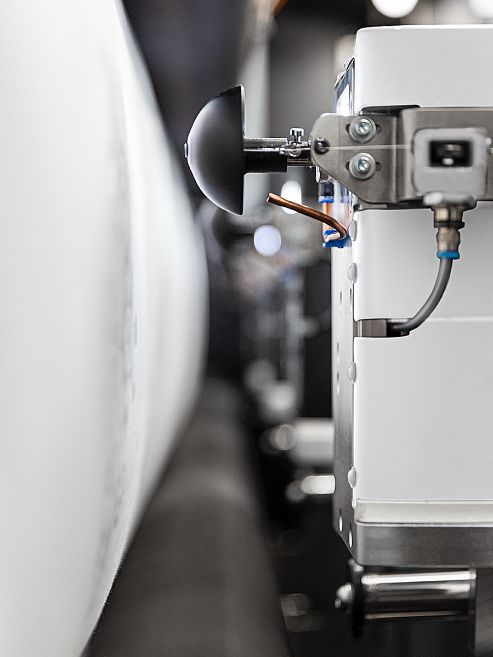

Own exclusive sewing-heads to deliver a high performance with an excellent seam

01.

HIGH PERFORMANCE, OWN AND EXCLUSIVE SEWING HEADS

Since our beginnings, we have considered that development and adaptation of sewing-heads to the specifics of their tasks, are key to achieve the needed flexibility in the production. Delivering a high quality seam and pattern accuracy, when working with a large range of thicknesses (between 1-8 cm).

02.

SEWING ENGINEERING

Research and development by our engineering team has resulted into a solid sewing system, built with a set of mechanical element with the purpose of giving response to a demanding market, challenging the production process day by day with new and thicker materials.

Powerful architecture to challenge high production demands.

Innovative system:

QMS “Quilting Motion System”

Quilted material flows vertically, through this new system that, synchronised with the transversal movement of the 4 independent sewing-heads achieves a high pattern and frame accuracy.

Sewing Quality

ClevDrawin’

Intuitive design creation

ClevDrawin´is a designing software to create patterns for quilted panels before loading them into the ClevOne. Provides full control over the panel pattern creation, with a large range of possibilities.

An easy interface that assists in the creation from scrap and in the modification of a quilted pattern.

Pattern Classification

Patterns can be assorted in 3 types, depending on the number of sewing-heads that participate simultenously in the quilting process:

(1 sewing-head)

(2 sewing-heads)

(3 to 4 sewing-heads)

(1 sewing-head)

(2 sewing-heads)

(3 to 4 sewing-heads)

01.

AUTOMATIC FRAME GENERATION

Focuses on framed patterns, assisting users with the creation of frames by introducing basic parametres.

02.

COMMAND CUSTOMIZING ORGANISATION OF SEGMENTS

Aids to optimize quilting pattern quality and manufacturing times by avoiding quilting gaps.

03.

SEWING-HEADS PARAMETRES

Allows to edit the sewing-heads settings within the pattern, such as: rpm, stitch length, … etc.

04.

CARBON COPYSUPPORT

Overlaps a selected image (fabrics and drawings) by placing it in the background, easing the creation of a pattern, and simulating it as a finished mattress panel.

05.

PATTERN CHECK

Verifies whether the pattern is configurated correctly or changes must be applied before launching it into production.

06.

PATTERN WORKING FLOWAND MEASURES

Shows each segment´s order and direction, in which the sewing-heads are to complete the pattern.

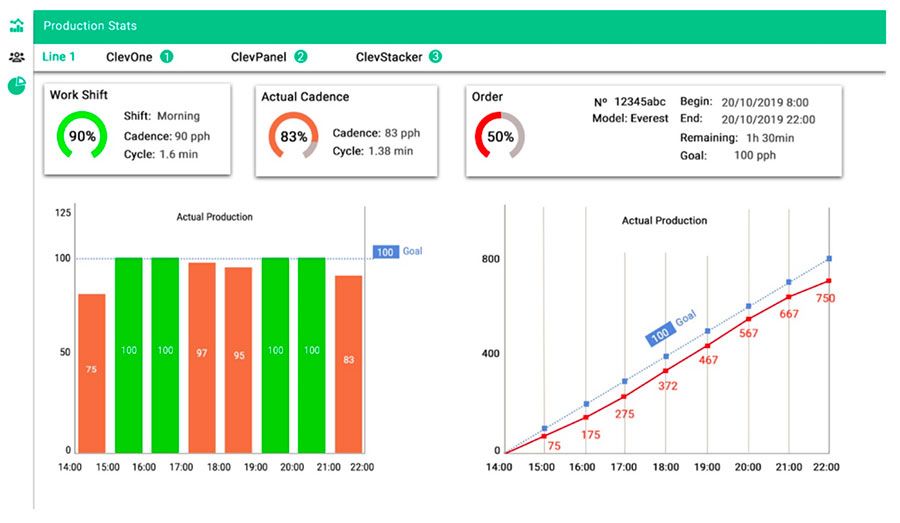

ClevDynamics

Management & production control

Automate and connect with your quilted panel manufacturing, providing efficiency and flexibility.

The current industrial revolution, Industry 4.0 and digitalization of processes, has motivated us to

develop a powerful software that enables

companies to manage their quilted panel production, by connecting different departments and users, feeding customized and valuable information to each of them.

Statistics

Interaction between ClevOne and its users, allows to follow-up production in real-time and machines running time and generate custom-made reports, assisting to the decision-making process.

Connect

The software enables users to create references according to their characteristics, (size, materials, patterns and quilts),

that can be used as tags in order to apply filters.

The production module eases production management and planification by importing (csv) or creating new orders.

Customers´ orders can be allocated with priorities or delivery dates and times, which might be used for organizing the production lists.

Operator

Production lists are transferred digitally and in real-time to the designated quilted panel production line. These lists are automatically arranged in an efficient manner to optimise resources and reduce changeovers.

By modeling the references, the ClevOne can follow-up consumptions and foresee material changes, notifying the operator and improving machines running time.

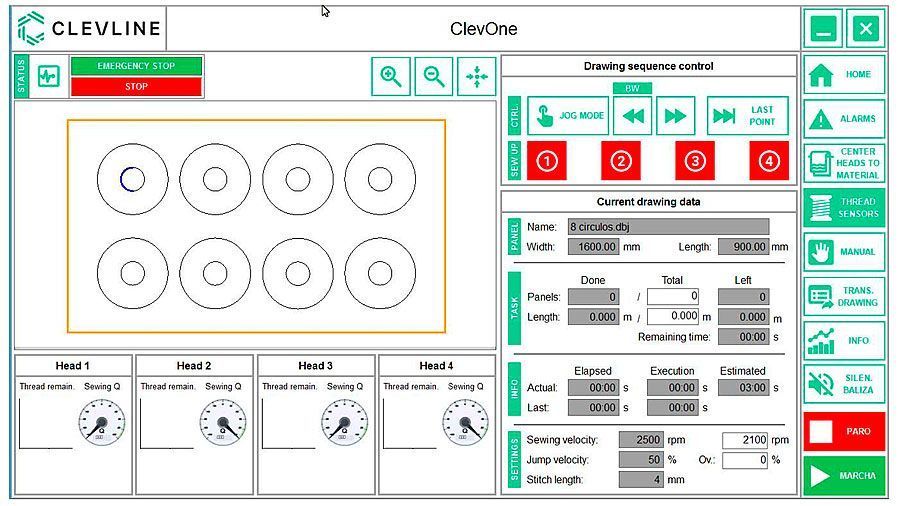

HMI Human Machine Interface

Maximum control and intuitive

Our HMI allows the the operator to interact directly with the ClevOne by loading ClevDrawin´ created patterns, that include ClevOne´s quilting parameters, such as the

number of sewing-heads that participate in the pattern quilting process, as well as the measures.

01.

OFFERS TWO WORKING MODES:

A. Manual Introduction:

Users introduce manually patterns and unit quantities for production.

B. Automatic Introduction (ClevDynamics):

Our production manufacturing module enables users to import production lists automatically, which is organised in a smart and dynamic manner, optimising resources and reducing manufacturing times by arranging production according to preferences: measures, materials and patterns.

02.

MANUAL CONTROL

Our HMI enables control and accessibility to the moving components of the ClevOne, as they are all electronically connected. Modes:

Production: operator may move manually all elements that take part into the feeding and quilting system.

Maintenance:technicians have access to all moving elements independently to complete machine´s check-ups.

03.

ADVANCED SETTINGS

The HMI gives access to technicians when adjusting the synchronism of the sewing elements (needle and bobbin-case).

Through these settings, ClevOne gives technicians, hassle-free alignment of the two-independent sewing-blocks (needle and bobbin-case), in each of the 4 freely moving independent sewing-heads.

04.

CENTERED FABRICS

ClevOne is integrated with a useful functionality for the operator to assure a centered input material, as the HMI allows to move the sewing-heads to find its border limits, in order to start the pattern centered.

Technical information

Production

Total quilting time:

96 seconds / panel.

* For this pattern

* Includes a sewing mark for ClevPanel´s cutting command.

Stitching speed: 2400 rpm

Stitch length:

· Internal frame at 5 mm.

· Internal motifs (x12) at 3 mm.

Electrical Data

Electrical installation: 3 p + tt

Phases voltage: 400 Vac

Minimum cable section: 10 mm

Power supply: 5 kW

· CO: 15 kW

· CO + CP: 20 kW

· CO + CP + CS: 22 kW

Mechanical data

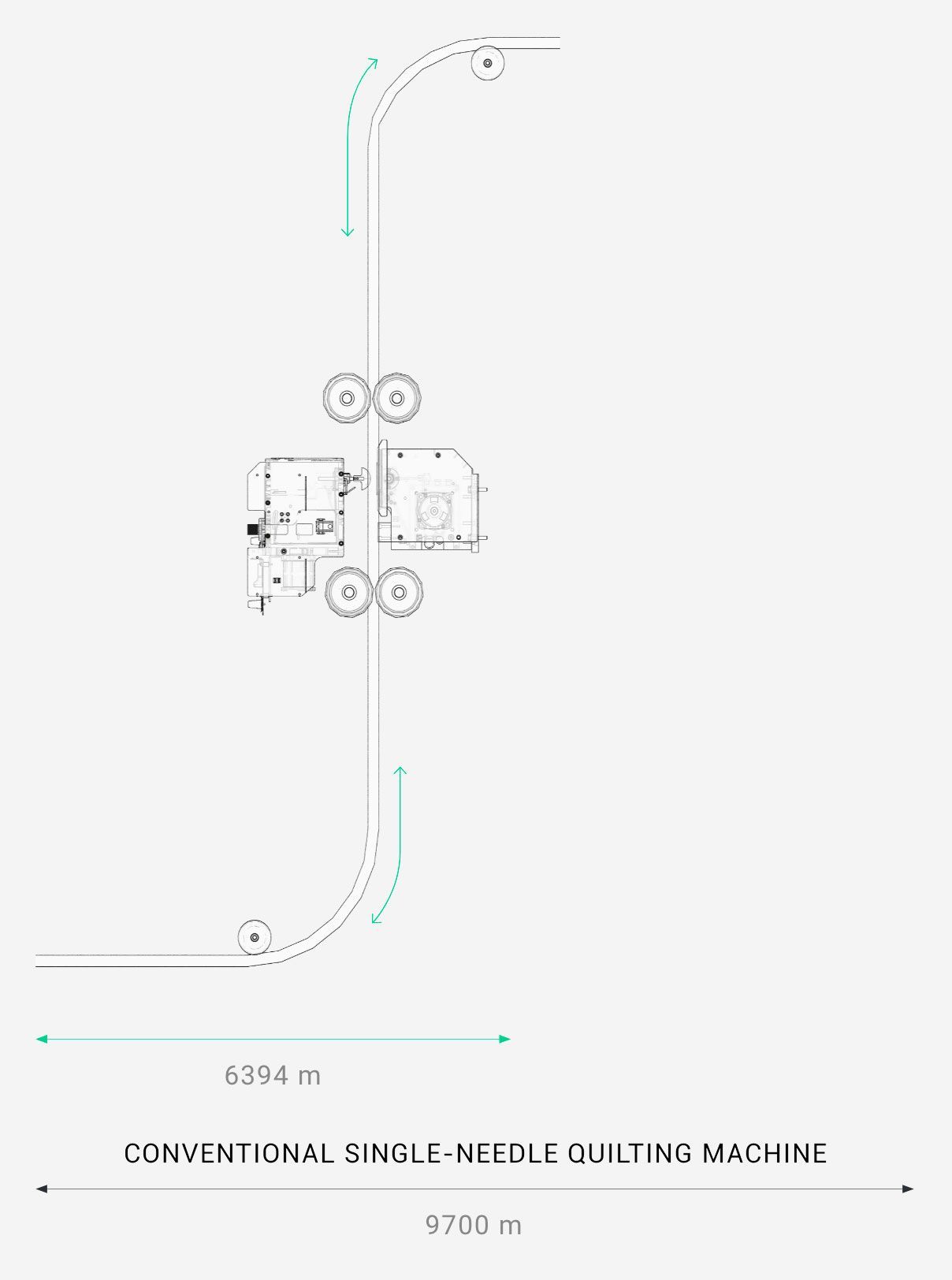

MACHINES DIMENSIONS (L x W x H):

· CO: 6400 x 5800 x 2300 mm

· CO + CP: 11400 x 5800 x 2400 mm

· CO + CP + CS: 14500 x 5800 x 2600 mm

WEIGHT:

· CO: 7400 Kg

· CO + CP: 9600 Kg

· CO + CP + CS: 10400 Kg

Pneumatic data

AIR CONSUMPTION:

· CO: 150 l/min

· CO + CP: 230 l/min

· CO + CP + CS: 250 l/min

Downstream air pressure: 6 bar

Operating data

INPUT MATERIAL:

· Width: up to 240 cm.

· Thickness: 1 – 8 cm.

· Filling: up to 5 layers

SEWING-HEADS:

· X4 independent sewing-blocks

· Bobbin-case XXL

· Automatic lubrication

· Working speed: up to 3000 rpm.

· Stitch-distance: 1 – 6 mm.

Related news

CLEVLINE

WHAT IS THE DIFFERENCE BETWEEN A CONVENTIONAL PRODUCTION PROCESS AND A FULLY AUTOMATED ONE?

Saber más

CLEVDYNAMIC

ClevDynamic: Discover how to take the step to digitalization and its multiple benefits.

Saber más

Fairs

Visit us at Interzum 2023! Discover our latest innovations for the mattress industry.

Saber más

Sin categoría

From May 4 to 7 we will participate in Interzum @ home, the first online version of Interzum.

Saber más

CLEVONE

ClevLine closer than ever

Saber más

CLEVONE

ClevOne video: high precision quilter

Saber más

CLEVONE

Discover the unique quilting machine that meets the new market demands

Saber más

CLEVPANEL

Visit us at our Interzum stand from May 21 to 25

Saber más