Once again, ClevLine will be present at Interzum Cologne, the international benchmark event for the furniture and bedding industry. As in previous editions, we bring our vision and commitment to show the world a new way of understanding production: more innovative, more conscious, more human.

At this special gathering, we will present our ClevLine, a revolutionary breakthrough that combines advanced automation, extreme precision, and true sustainability. It is not just an evolution in efficiency and productivity: it is a leap towards Industry 5.0. An industry where flexibility, sustainability, and the human-machine factor intertwine to shape smarter, more respectful, and people- and planet-centered production processes.

Thanks to the integration of multiple functionalities and its unique features, we offer the market an innovative concept that breaks with the conventional, completely redefining the quilting industry. Every small detail reflects our commitment to providing not just machines, but genuine solutions that evolve alongside the market’s needs.

At ClevLine, we understand that true progress is not just about producing more, but about producing better: better for companies, better for workers, better for the world. Flexibility, Sustainability, Humanity are not just words accompanying our brand. They are the principles guiding every decision, every innovation, and every advancement towards Industry 5.0.

Would you like to know more about us? Come visit us at Hall 09 | Stand A050-B051.

In a world where efficiency and quality are essential in any production process, automation is presented as a solution that not only improves processes, but also redefines the way in which they are conceived and executed.

At ClevLine, we have always been committed to innovation and technology in order to offer our customers highly flexible solutions that allow them to remain competitive over time. Thanks to these values and after years of study and development, we have provided the market with a totally innovative concept in the mattress industry: A fully automatic production line for quilted panels, covers and borders, which also combines the functionality of a multi-needle and a single/double-needle in the same machine, being able to work with a multitude of framed, centred, tack & jump and continuous designs.

In this publication, we will explore in detail how our automatic production line has come to revolutionise the way you manufacture your mattresses, offering advantages that go far beyond efficiency.

The Conventional Process: A Sequence of Workstations

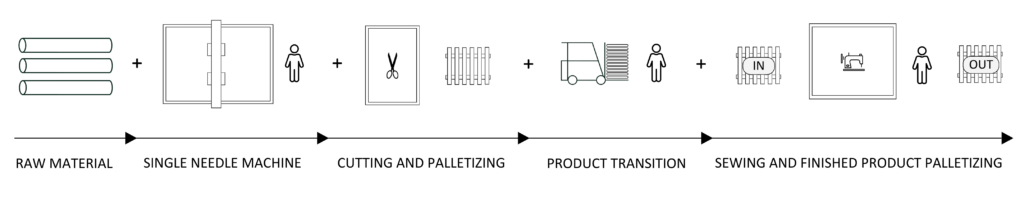

Let’s first talk about what a conventional production process is like. As you all know, the panel production process starts with the preparation of the rolls of raw material, passing through the different quilting, cutting and hemming stations, ending with the palletisation of the finished panels. Afterwards, these panels are transferred to the assembly section, where they will be used for the top and bottom of the mattress.

But how is this production process usually carried out? It depends on how the production plant is organised and the type of machinery available. Therefore, based on our experience with different customers, you will find below the process faithfully represented by a series of graphics:

The Automatic Revolution: Integration and Efficiency

Having seen a fairly common conventional production process nowadays, with the number of stations and operators that usually make it up, let us introduce you to how we approach this production process with our CLEVLINE automatic line.

As in the previous case, we start from the raw material rolls to the palletising of the finished product, with the great difference of not requiring any intermediate handling of the product and including all the quilting processes in the same workstation, where only one operator is needed to supervise and control the entire line.

CLEVLINE has a modular architecture, composed of three independent modules that work together for a common purpose:

CLEVONE: Vertical quilting module with four independent sewing heads, qualified to work with all types of designs and a wide variety of materials and thicknesses, guaranteeing a quality finish on each panel.

CLEVPANEL: Automatic hemming module to finish the perimeter of the panel, with high precision in the measurement, reducing the number of workstations and facilitating the subsequent closing of the mattress.

CLEVSTACKER: Automatic stacking module for a higher level of autonomy in the process, eliminating repetitive tasks of low value for the operator.

Competitive Advantages:

In addition to improving the production process and the quality of the end product, our automatic line offers a host of unrivalled benefits:

1

Increased Efficiency: With a continuous and uninterrupted work sequence, downtime is minimised, resource utilisation is optimised and, as a result, overall process efficiency is increased.

2

Reduced Costs: By eliminating manual handling of products at different stages of the process, labour and production costs are significantly reduced.

3

Space Optimisation: By integrating all processes into a single workstation, the need for additional space and machinery is reduced, leading to considerable savings in floor space.

4

Improved Product Quality: The automation of processes reduces the risk of damage and flaws during the manufacturing process, ensuring greater consistency in the quality of the final product.

5

Flexibility and Adaptability: Our line allows quick and precise adjustments according to specific production needs, combining the functionality of a multi-needle and single/double-needle in the same machine.

6

Greater Process Control: Automation allows greater control and supervision of the production process, as all parameters and variables can be monitored and adjusted in real time.

7

Operator Care: It frees the operator from repetitive and routine tasks, allowing them to focus on higher value activities such as production process supervision, quality control and problem solving, providing them with greater job satisfaction.

The first 100% digital edition of Interzum will take place from May 4 to 7, 2021, and ClevLine will be present at it!

Due to the current situation, a completely virtual stage has been created to hold one of the leading trade fairs in the mattress sector.

From Interzum @ home you will be able to speak directly with our team, arrange a visit to see the complete line in full operation, download our catalogs, and see everything we have prepared for you.

Soon we will provide the link so you can come and be part of this new experience!

Never has been so easy to be at Interzum

In the times we are living, we believe the best way to be near you is open the doors of our company.

ClevLine wishes you all the best, let’s get through this together!